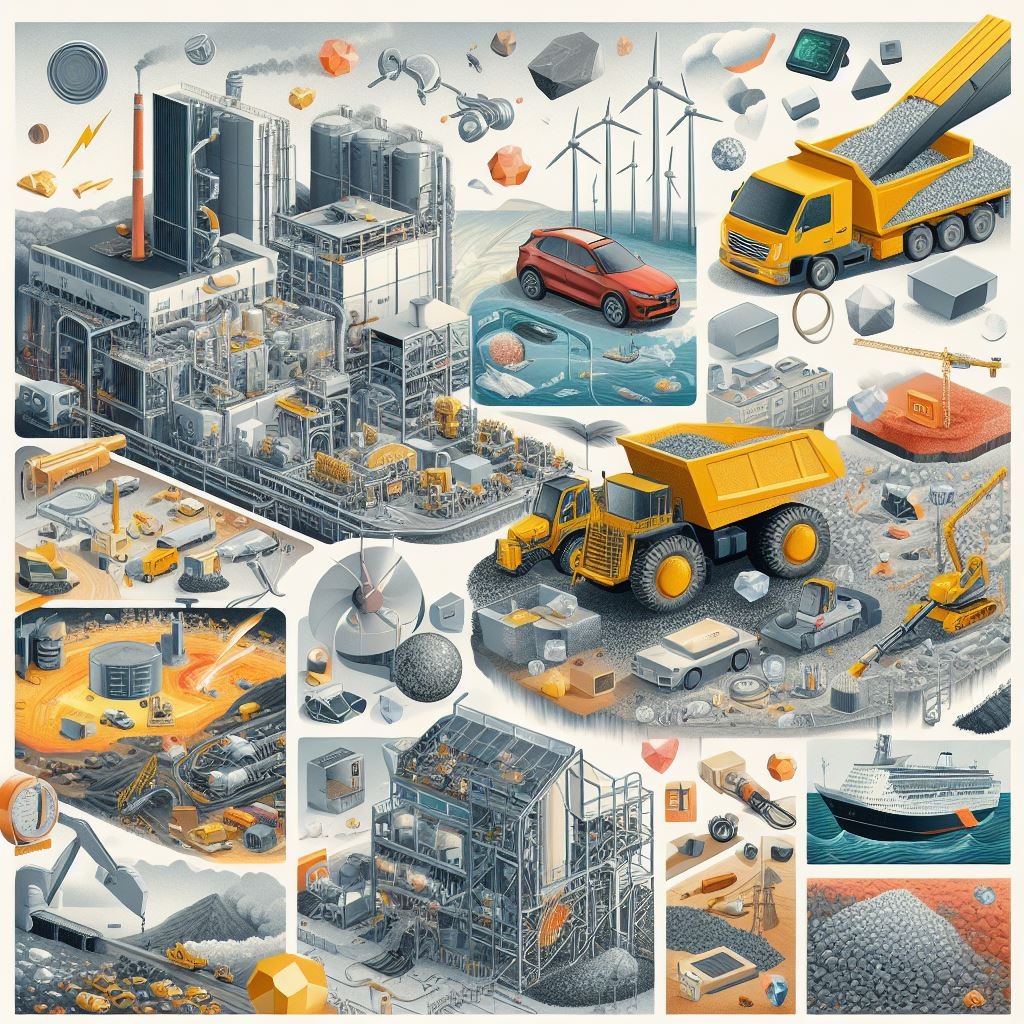

Critical raw materials and chemical refining processes

One of the most important directions in the development of circular economy in Ida-Viru County is the use of materials deposited in the environment. Four projects, led by researchers from the University of Tartu, are investigating the chemical processes involved in the refining of mineral waste and the extraction and deposition of rare earths.

Extraction of rare earth elements with ionic liquids

Demand for rare earths will grow significantly in the coming years. They are needed in catalysts for the chemical industry, in green energy technology devices as well as in medicine and light sources. Rare earths are associated with high supply risks, making it crucial to develop production methods that improve their availability.

The aim of the project is to develop a novel stepwise method for the extraction of rare earths from acidic aqueous phosphorus solutions using ionic liquids or mixtures of ionic liquids and to introduce an energy-efficient and less effluent-generating extraction method. At present, there is no complete ionic liquid extraction circuit in the world that would allow environmentally sound extraction of all rare earths as well as scandium and yttrium as pure components from complex raw materials and enriched ores. The results of the project would address this bottleneck.

Electrochemical deposition of rare earths and production of nanopowders

The transition to renewable energy in both the energy and industrial sectors increasingly requires the exploitation of geological resources and alternative, less polluting technologies for their exploitation. In Estonia, one such raw material is phosphate ore, which also contains a considerable amount of rare earth elements. Their extraction would make it possible to develop an industry, both in Estonia and in the European Union, which depends in particular on the availability of rare earth raw materials.

The aim of the project is to develop electrochemical deposition technology for heavy and light rare earths using energy-efficient ionic liquids and mixtures. For this purpose, concentrates of rare-earth separates are used, which can be extracted by co-electrolysis. Electrochemical deposits are purified in a reducing gas environment to obtain nanopowders.

The main raw material for the extraction of rare earths in Estonia is phosphorite ore, but also waste from the former Estonian phosphorite industry, as well as suitable mineral residues from the chemical extraction of mineral raw materials in Ida-Viru County. The new method would be 2–5 times more energy-efficient than the existing ones and produce 10 times less wastewater.

It would also be suitable for smaller manufacturing companies.

Mineral waste refining technologies in Ida-Viru County

Over the decades, the Estonian oil shale industry has accumulated large amounts of waste from both mining operations and oil shale processing. Most of these are hydrated shale ash sediments of different origin and composition. Recovery of nuclear waste from the shale industry has been very limited. Less than 5% of the ash generated in a year is used. The reprocessing of landfilled nuclear waste has not been particularly addressed.

The main objective of the project is to find ways to use residual materials from the oil shale industry as secondary raw materials for the production of high value-added binders and building materials. To this end, the focus will be on the mechano-chemical reactivation of landfilled ash and ash waste, enabling the reuse of waste as alternative alkali-activated binders. This will help to reduce both the need for new mineral extraction and the environmental footprint of existing cement-based binder production processes.

Distribution, characteristics and recovery potential of industrial solid waste in Ida-Viru County

Around one billion tonnes of oil shale industry waste is concentrated in Ida-Viru County, with little (re)use, but which could and should be a valuable secondary raw material for various industries. At the same time, the fact that these wastes have different origins, compositions and evolutionary trajectories complicates their uptake.

Our project deals with the systematic investigation of the composition and heterogeneity of solid industrial waste in Ida-Viru County. We will draw up an overview of waste and, in cooperation with companies, explore the best ways to recycle it, both in the chemical industry and in the production of building materials or aggregates.

By the end of the project, there must be a clear overview of the quantities and composition of the different types of waste. This will help to identify the most appropriate technologies and their economic potential for recycling industrial waste. This could be valuable information for companies in Ida-Viru County to make investments and start production.